Medical supplies are used for a variety of purposes. They enable certain medical procedures, help to keep track of someone’s health, and even provide important protection for patients during treatment, among other things. One thing that is common across all medical supplies is how complex it is to make them. This article will explore what goes into the production of medical supplies, from the supply chain to the different types of supplies, and give you a better understanding of the process.

1. Who Makes The Supplies?

Most medical supplies that you can think of go through a process called medical device contract manufacturing. This is where the design and development of the product are taken over by a third-party company, and they actually make it for you. As the medical device manufacturing market leaders Polarseal have shown, it’s important that these companies are able to provide orders in high volume and in a timely fashion. By having established companies that specialize in this kind of work being able to take care of different supply needs, the costs of producing medical devices, or parts of them, go down, which means they are more widely accessible. Of course, all the materials used in the production of these devices must be confirmed as safe by an extensive testing procedure.

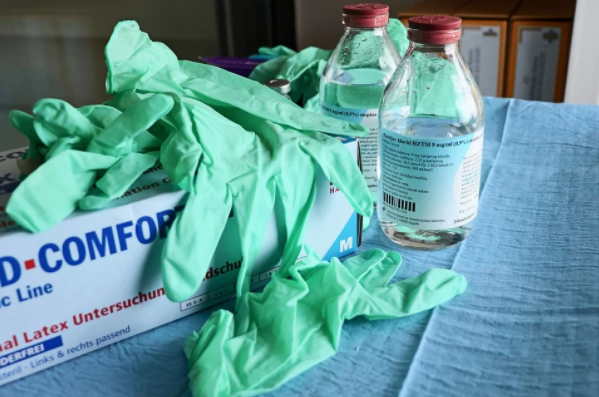

2. Clinical Supplies

Clinical supplies are used for different purposes. Depending on the treatment that is going to be done, a variety of clinical items will be needed. Examples include gauze, syringes, and anything that has to do with taking care of a patient’s eyesight. This may be the kind of medical supply you encounter most frequently. The production process for these kinds of supplies mostly includes the packaging and final labeling, where they are put in containers to be distributed. Since these are the most often used items – a gauze for example is not only used in hospitals but is also a part of any first aid kit intended for personal use, it’s important that these kinds of supplies are made in a way that will make them affordable, resilient to different uses, and of course, safe. Because it is expected that the clinical equipment will only be used once, extensive research into how effective they can potentially be has led medical device manufacturers to establish different processes for ensuring their sterile nature.

3. Pharmaceutical Supplies

These are the types of medical supplies that you’ll find in pharmacies all over town. The production process includes raw material supply, quality control, packaging and labeling, transit to the distribution centers – these are just some parts of their complex path to retailers everywhere. Pharmaceutical materials are made according to standards that include both human and environmental protection, which means they can’t be produced using certain substances. There’s also the question of copyrights of sorts – just because a pharmaceutical company might have produced a certain medicine, doesn’t mean they are the only ones to do so. On the other hand, even if a company knows how to make a certain medicine, it may not be allowed to do so if the owners of the patent on that medication don’t approve of it. To put it more simply – there are specific medication-making procedures that must be followed, and this includes respecting all kinds of standards set by international organizations.

4. Hospital Supplies

Compared to clinical supplies, hospital supplies are much larger and more expensive items. They include oxygen tanks, bedding, and even beds themselves. This means that the process of production must go through more phases than just assembly, and many times it is carried out by companies specializing in medical equipment. Of course, there are some parts to these devices that will be manufactured separately and then put together. For example, a hospital bed might have its frame assembled at one place and the mattress somewhere else – the finished product is the only one that’s allowed to be called a “hospital bed” with all its attendant benefits. When it comes to the more expensive devices, which are expected to be used for many years without being replaced, the companies manufacturing them will often conduct extensive research into how to ensure their durability and safety. The materials used must be resistant to bacteria, and easy to disinfect.

5. Surgical Supplies

Surgical supplies are for more serious procedures, which means the demand for them is higher. This also results in a greater variety of materials that could be used to make different kinds of tools and equipment. Some examples include surgical lasers, carbon dioxide lasers, electrocauterization equipment, endoscopic instruments, suction equipment, bone drills, hypodermic needles and accessories, masks for anesthesia, breathing apparatus, catheters, infusion pumps – the list goes on. These are tools that require not just being safe during contact with human bodies but also resistance to wear and tear after repeated use. Since they are used to help people recover from serious illnesses or injuries and to perform complicated invasive procedures, it is crucial that these tools are of high quality and provide the best results. The standardization of the production process ensures that these products are safe for use, intuitive to use by medical personnel, and extremely effective in the procedures they are used for.

While the production of medical supplies contains even more elements than listed in this article, the ones mentioned can give a good idea of what’s involved in the process. From research and development to planning and design, these phases must include a variety of elements that help ensure that the final product is safe for both humans and the environment, all while being produced in a way that makes their use plausible on mass.