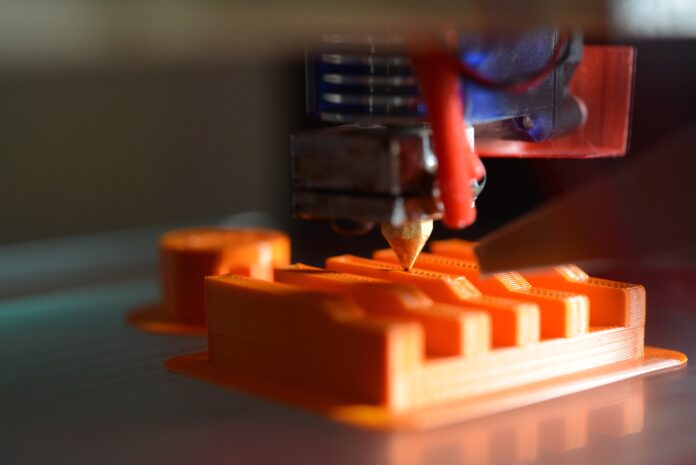

Markforged, a leading provider of industrial 3D printing solutions, has been making waves in the manufacturing industry with its groundbreaking technology and innovative approach. Since its inception in 2013, Markforged has been on a mission to empower manufacturers to create strong, durable, and functional parts using advanced additive manufacturing techniques. By combining the benefits of traditional manufacturing processes with the flexibility and efficiency of 3D printing, Markforged has transformed the way industries design, prototype, and produce parts.

With a focus on delivering industrial-grade 3D printers, Markforged has gained recognition for its commitment to quality and precision. The company’s printers are known for their ability to produce robust parts with high strength and accuracy, making them suitable for a wide range of applications across industries such as aerospace, automotive, healthcare, and more. Markforged has successfully bridged the gap between prototyping and production, enabling manufacturers to rapidly iterate and produce functional parts on demand.

One of the key aspects that sets Markforged apart is its unique approach to 3D printing. Unlike traditional 3D printers that primarily use plastics, Markforged printers leverage a variety of materials, including carbon fiber, Kevlar, fiberglass, and metal, to create parts with exceptional strength and durability. This ability to reinforce parts with composite materials makes Markforged printers ideal for producing end-use parts that can withstand demanding environments and rigorous applications. By offering a range of materials to choose from, Markforged empowers manufacturers to select the most suitable material for their specific requirements, ensuring optimal performance and functionality.

Markforged’s commitment to precision and accuracy is evident in its advanced printing technology. The printers employ sophisticated systems and software algorithms to ensure precise layer-by-layer deposition, resulting in parts with tight tolerances and excellent surface finish. This level of precision is critical, particularly in industries where parts need to fit seamlessly, interact with other components, or meet stringent quality standards. Markforged printers deliver consistent and reliable results, enabling manufacturers to produce parts with confidence and efficiency.

In addition to its cutting-edge printers, Markforged offers a comprehensive ecosystem of software and tools that streamline the entire manufacturing process. The company’s cloud-based software, Eiger, provides a seamless workflow from design to print, allowing users to upload, prepare, and optimize their models for printing. Eiger’s intuitive interface and powerful features simplify the design process, enabling users to make modifications, apply supports, and optimize part orientation to achieve the best possible results. This integration of hardware and software ensures a seamless user experience and maximizes the efficiency of the printing process.

Markforged’s impact extends beyond individual printers and software. The company has created a global network of customers and partners, fostering collaboration and knowledge sharing within the manufacturing community. Through its online platform, Markforged Connect, users can access a vast library of resources, including case studies, best practices, and design guides, to enhance their understanding and application of 3D printing in manufacturing. This community-driven approach encourages innovation, problem-solving, and the exchange of ideas, creating a collaborative ecosystem that benefits all stakeholders.

One of the significant advantages of Markforged’s industrial 3D printing solutions is the reduction in time and cost associated with traditional manufacturing processes. By eliminating the need for tooling, machining, and assembly, Markforged enables manufacturers to accelerate their production cycles and bring products to market faster. The ability to iterate designs quickly and produce functional prototypes on demand allows for rapid product development and iteration. This agility is particularly valuable in industries characterized by short product lifecycles and intense competition.

Moreover, Markforged’s approach to 3D printing aligns with sustainability goals and environmental stewardship. The additive manufacturing process generates less waste compared to traditional subtractive methods, as it only uses the necessary amount of material required for the part. Additionally, the ability to produce strong, lightweight parts reduces the overall weight of assemblies, resulting in energy savings during transportation and usage. Markforged’s commitment to sustainability resonates with manufacturers seeking to minimize their environmental footprint and adopt more eco-friendly production practices.

In conclusion, Markforged has revolutionized the manufacturing industry with its industrial 3D printing solutions. By combining advanced additive manufacturing techniques, a wide range of materials, precision engineering, intuitive software, and a collaborative community, Markforged has empowered manufacturers to create strong, functional, and cost-effective parts with unparalleled efficiency. As the adoption of 3D printing continues to grow, Markforged is poised to play a crucial role in reshaping the future of manufacturing, driving innovation, and unlocking new possibilities across industries.

Material Versatility:

Markforged offers a wide range of materials for industrial 3D printing, including carbon fiber, Kevlar, fiberglass, and metal. This material versatility allows manufacturers to produce strong and durable parts for various applications.

Strength and Durability:

Markforged’s unique approach to 3D printing enables the reinforcement of parts with composite materials, resulting in exceptional strength and durability. This makes the printed parts suitable for demanding environments and rigorous applications.

Precision and Accuracy:

Markforged printers employ advanced technology and software algorithms to ensure precise layer-by-layer deposition, resulting in parts with tight tolerances and excellent surface finish. This level of precision is crucial in industries where parts need to fit seamlessly and meet high-quality standards.

Integrated Software Ecosystem:

Markforged provides a comprehensive software ecosystem, including the cloud-based software Eiger, which streamlines the design-to-print workflow. The software simplifies model preparation, optimization, and supports generation, enhancing the efficiency of the printing process.

Collaborative Community:

Markforged has created a global network of customers and partners through its online platform, Markforged Connect. This community-driven approach fosters collaboration, knowledge sharing, and access to valuable resources, empowering users to maximize the potential of industrial 3D printing.

Markforged has emerged as a leading player in the realm of industrial 3D printing, revolutionizing the manufacturing landscape with its cutting-edge technology and innovative approach. The company’s journey began in 2013, driven by a vision to transform the way industries design, prototype, and produce parts. Since then, Markforged has been on a relentless mission to empower manufacturers by bridging the gap between traditional manufacturing processes and the endless possibilities offered by additive manufacturing.

In the world of manufacturing, precision and reliability are paramount. Markforged has positioned itself as a reliable partner for industries seeking high-quality and accurate parts. The company’s commitment to precision is evident in every aspect of its operations, from the design of its printers to the advanced algorithms embedded in its software. Manufacturers can rely on Markforged to deliver parts with tight tolerances, ensuring a seamless fit and optimal performance.

One of the game-changing aspects of Markforged’s approach is its emphasis on strength and durability. Traditional 3D printers often produce parts that are suitable for prototyping or non-functional applications. Markforged, however, has taken a giant leap forward by incorporating composite materials into its printing process. By reinforcing parts with materials such as carbon fiber, Kevlar, and fiberglass, Markforged has unlocked a new realm of possibilities for industrial applications. The resulting parts are not only lightweight but also possess exceptional strength and resilience, making them suitable for demanding environments and challenging applications.

The benefits of Markforged’s industrial 3D printing solutions extend far beyond the production floor. They have a profound impact on the entire manufacturing ecosystem. By enabling manufacturers to produce parts in-house, Markforged eliminates the need for outsourcing and long lead times associated with traditional manufacturing methods. This newfound agility allows manufacturers to respond rapidly to market demands, iterate designs quickly, and bring products to market faster than ever before. The ability to reduce time-to-market significantly gives companies a competitive edge and allows them to stay ahead in today’s fast-paced business environment.

Moreover, Markforged’s approach to 3D printing aligns with sustainability goals and eco-friendly practices. Traditional manufacturing processes often result in significant material waste due to the need for machining and subtractive methods. In contrast, additive manufacturing generates less waste as it only uses the necessary amount of material required for the part. Furthermore, Markforged’s ability to produce lightweight parts contributes to energy savings during transportation and usage. By adopting Markforged’s industrial 3D printing solutions, manufacturers can minimize their environmental footprint and embrace more sustainable manufacturing practices.

Markforged’s impact extends beyond individual manufacturers. The company has fostered a vibrant and collaborative community that spans industries and geographies. Through its online platform, Markforged Connect, users can access a wealth of resources, including case studies, best practices, and design guides. This community-driven approach promotes knowledge sharing, problem-solving, and the exchange of ideas. Users can connect with like-minded individuals, learn from each other’s experiences, and unlock new possibilities through collective innovation. This collaborative ecosystem not only empowers individual manufacturers but also drives industry-wide advancement and pushes the boundaries of what is possible with industrial 3D printing.

In conclusion, Markforged has reshaped the manufacturing landscape with its industrial 3D printing solutions. By combining precision, strength, agility, and sustainability, the company has positioned itself as a leader in the field. Markforged’s commitment to delivering high-quality parts, its unique approach to materials, and its dedication to fostering a collaborative community have made it a trusted partner for industries seeking to unlock the full potential of additive manufacturing. As technology continues to evolve, Markforged is at the forefront, driving innovation, enabling new possibilities, and empowering manufacturers to embrace the future of manufacturing with confidence.